Chromed Rod

- Description

- RFQ

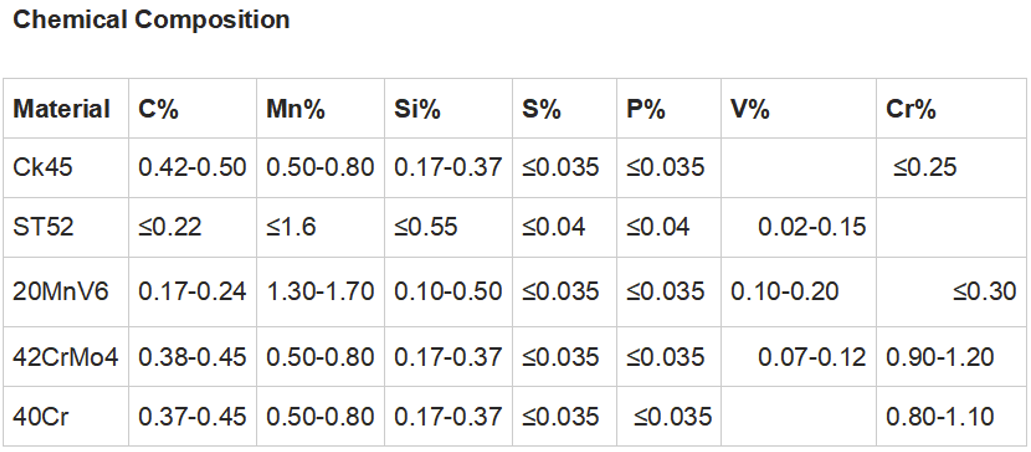

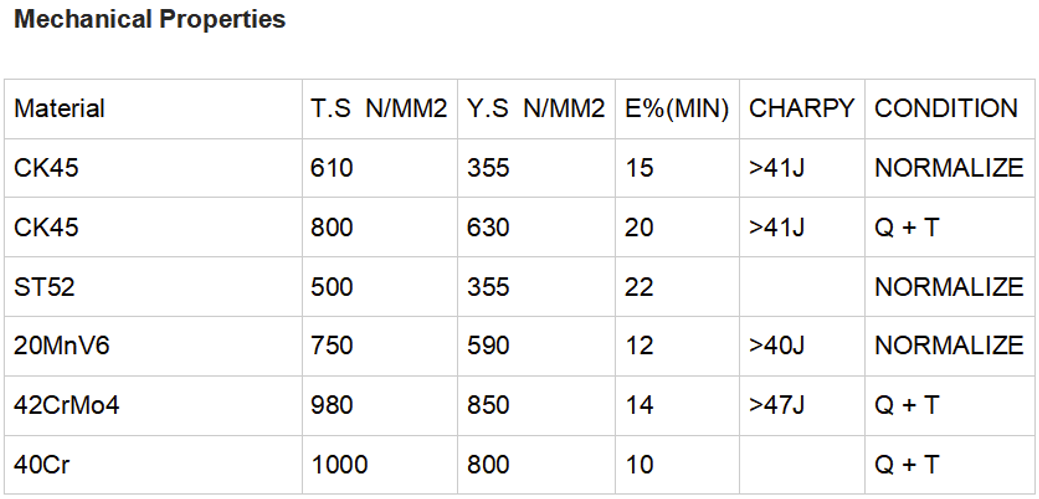

Material: CK45, SAE1045, 4140, 4340, JIS45C, 40Cr, 20MnV6, 42CrMo, SS431, SS430, Stainless Steel 304/316/2205, etc.

Type: Chrome Plated Bar/Chrome Plated Rod/Nickel-Chrome Plated Rod/Hollow Chrome Bar/Hollow Bar

Heat Treatment Type: 1) Normal no heat 2)Q+T(Quenched+Tempered) 3)Induction Hardened

Diameter: Φ 6-800mm

Length: max.20 meters

Chrome layer: min 20/25/30/50 Micron or customized

Straightness: <= 0.5/1000

Roughness: Ra <= 0.4u

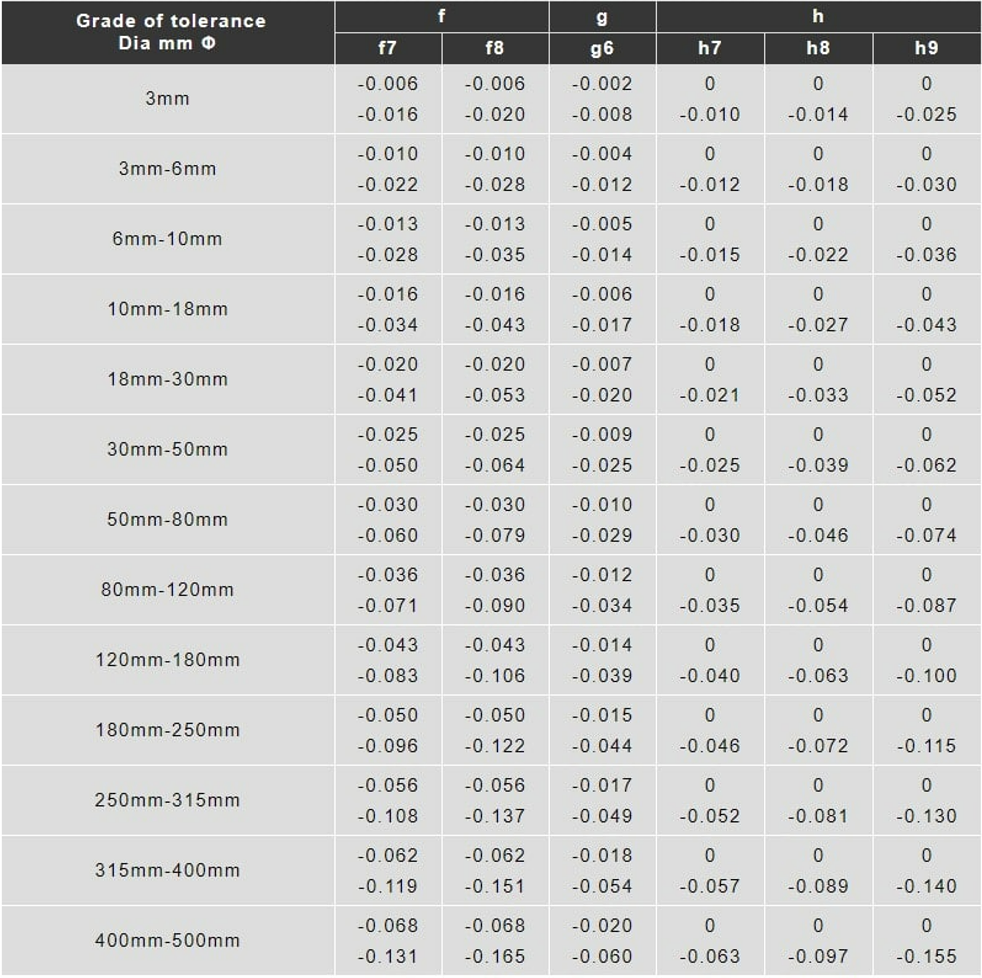

Diameter tolerance: ISO f7/f8/f9/h8/h9 or as request

Protection: Anti-rust oil outside with hard board sleeve protection.

Packing: Wooden case

WHAT IS THE ADVANTAGES OF OUR CHROME PLATED ROD?

- Carbon steel balances durability, hardness, and wear resistance using formability, weldability, and durability;

- Chrome plating provides corrosion resistance along with an Extremely reflective look

- High precision tolerances, which ensures when used to make hydraulic piston rod, it can fit the cylinder precisely.

- Good Hardness: the surface hardness attaining HV850 minimal and upward, which not only help improve wear resistance but also help extend the life span of these chrome plated rods, thereby helping the consumer save the cost.

HERE BELOW IS THE APPLICATION LIST OF THE CHROME RODS:

- Hydraulic cylinders (chrome plated piston rods)

- Pneumatic cylinders / air cylinders (hydraulic cylinder piston rods)

- Guide rods for plastic manufacturing machine and hydraulic machinery

- Rollers for machines, such as packing machine rollers, printing machine rollers

- Shaft for machinery, such as Textile machinery center axle, Transport machinery center axle, etc.

- Ejector rods for injection molding machines

- Vibration absorbers and pistons for some industrial machinery.